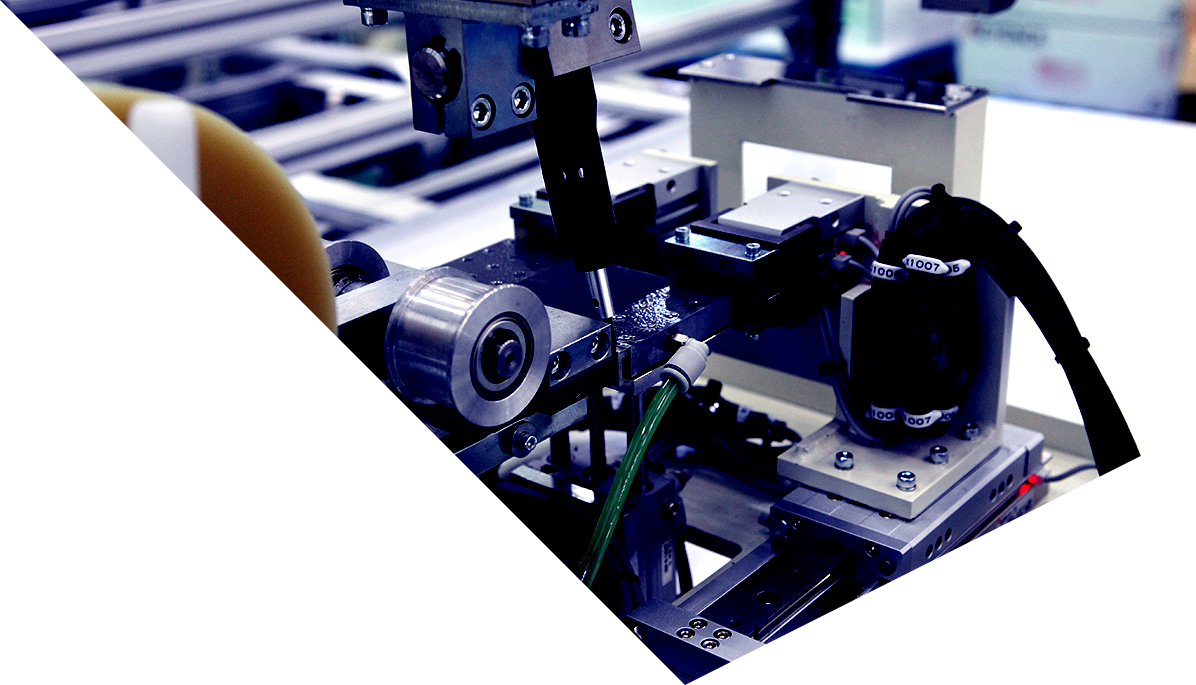

We specialize in the development and manufacturing of production equipment primariIy for the glass and stee I industries in Japan. With our integrated production system, we are dedicated to meeting a wide range of customer demands and requirements.

ABOUT NAKASAKU

Nakasaku Co., Ltd. carries out manufacturing and assembly, attachments and test runs of industrial machines and equipment in such areas as Iron and Steel, Industrial Electronics, Automobiles and Glass in Japan.

Everything we produce is made to order. We will work on development with customers.

Design, Electric design, Assembly,Electrical control work, and Installation.